Neos Stretch Mobile Wrapper - Doverco

150-180 Wraps/Charge

Maximum Safety

Easy-To-Move

Overview

This top-ranked model is the only robot that can use ARYA, a new patented technology that makes the wrapping process fully automatic. Neos is a breakthrough in semi-automatic stretch wrappers as it doesn't need operator intervention to attach the film to the pallet, completing the cycle automatically without using compressed air or mechanical parts that wear out. Its dual-motor PS pre-stretching carriage ensures the lowest film consumption and highest reliability in the market. Compared to the Sfera Neos series, it has increased battery capacity to 220V and a new, easy-to-program 7-inch touch screen interface.

The Neos mobile pallet wrapper wraps palletized loads in less than a minute…any size, shape or weight

Save time and money for the wrapping operation.

- The patented optional arya system performs the wrapping cycle fully automatically

- Possibility to adjust tension on load and pre-stretch in every step of the wrapping cycle

- Motorized pre-stretch system with 3 driven rollers electronically controlled with interchangeable ratios: 150-200-250%

- Made for the highest security and safety of the user

Operating Panel

- 7'’ Touch screen

- 99 Programs

- Many pallet sizes can be programmed on the panel

Optional Arya System

- Revolutionary patent that makes automation affordable. The optional Arya Systems transforms your semiautomatic wrapping machine into a fully automatic one.

Easy Fil Change

- Easy reel change

- Adjustable service height

NEOS

OPTIONAL

FE

CARRIAGE FE

ARYA

FM

CARRIAGE FM

STRETCHFILM CUTTER

WRAPPING HEIGHTS

Technical Specifications

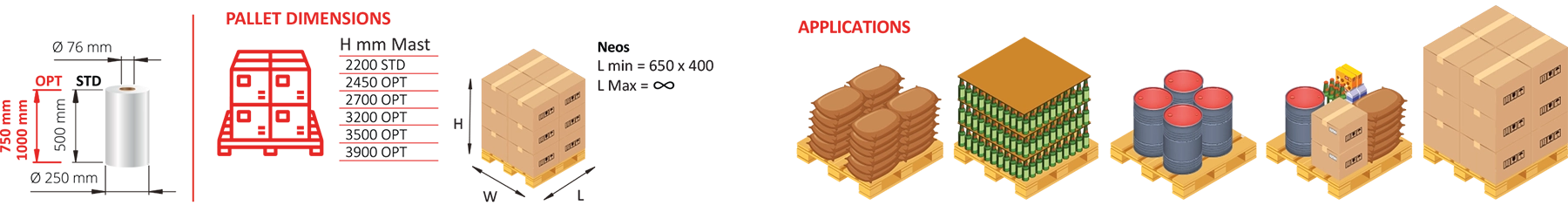

Wrapping programs model NEOS Min pallet dimension

Operating display 7" TOUCH with 99 Programs 650 x 400 mm

Max pallet dimension

Pallet size can be programmed on the operating panel

Adjustable speed facilitated by frequency changer

Max 65 m/min

Carriage braking system

FM (FTL=Force to load)

Standard wrapping height

2200 mm

Optional wrapping height

2400/2700/3000/3500 mm

Photocell detection of load height

STANDARD SUPPLY

Adjustable Spool carriage speed facilitated by inverter

From 1,3 up to 5,4 m/min

Upwards Spool carriage speed

Independently settable

Downwards Spool carriage speed

Independently settable

Lifting with fork lift truck

STANDARD SUPPLY

Total installed power

0.55 Kw

High frequency built-in battery charger

230 V - 50/60 Hz

Standard charging voltage

230 V - 50/60 Hz - 1 Ph

Operating voltage

24 V

Electrical and motor protection system

IP 20

Output capacity

35 Pallets per Hour **

* Depending on configuration

Wrapping conditions and pallet dimensions have an influence on the Max output capacity

** Depending on film quality and working environment